QI Essentials: Developing Improvement Capability

17th September 2019

Developing improvement capability has the potential to deliver a step-change in organisational performance, but only if done in the right way. Have a read of Amar’s latest QI Essentials Blog…

The landscape of healthcare improvement in England is massively different to 2013 when we were planning the start of our improvement journey at ELFT, feeling our way into a fairly uncertain world. Almost all NHS providers are now using quality improvement, although it’s probably fair to say, with some variation in application and belief. One commonality across all our organisations is the need to build improvement capability.

Why is this the case? It remains a rarity for training curricula in any healthcare professions to incorporate learning about how to improve complex systems. Seems strange, as that’s what many of us spend our working lives pursuing. A few training institutions are now embedding quality improvement into undergraduate and postgraduate training, such as Sterling University, Salford University and City University, but most providers still recruit a workforce that is largely naïve to healthcare improvement, and so we have to develop these skills on the job. This makes developing improvement capability a key task for organisations that intent on pursuing continuous improvement, but also runs the risk of quality improvement being viewed as training or a set of skills that can be learnt in a classroom.

Having focused on building improvement capability for over five years at ELFT, here are some of my key learnings. Developing improvement capability has the potential to deliver a step-change in organisational performance, but only if done in the right way. Viewing this key enabler of continuous improvement as ‘training’ is a classic error. Building capability is about developing skills, but also about activating people with these new skills and providing support to help them apply these to real-life problems. The theory of quality improvement is pretty straightforward. It’s the application that is difficult. Improvement capability needs to focus on practising the theory and tools of improvement to solve issues in the workplace.

So, my first learning has been to avoid training people in quality improvement without having a mechanism to apply these skills to solving real quality problems. Our key vehicle for quality improvement capability building at ELFT has a requirement for all participants to bring a quality issue that the team has agreed they will work on, and to apply the learning to this project over the course of the programme.

It follows that capability building ought to then be structured around the life cycle of a project, and provide an opportunity to learn from the design stage all the way through to implementation. A minimum time scale for this should be six months, to really enable people to learn about good improvement design, planning, testing, measurement and implementation.

My second learning is about modelling an improvement mindset in the way that we develop improvement capability. We improve in partnership – whole multidisciplinary teams together with patients, service users and families. So, our capability building programmes ought to model this, and bring together a diverse group of people to learn and practise together. All our improvement capability programmes at ELFT are open to all, and we avoid separate disciplines learning about quality improvement in isolation of others. We want quality improvement work to feel energizing and fun, so we bring these elements into our capability building too, with plenty of exercises, games and creative activities.

Lastly, improvement is all about trying something, reflecting and adapting. So we ought to apply this to our capability building too. Capture data, in real-time, to understand the experience of those involved, and make adaptations to keep iterating your programme. This kind of real-time evaluation is key to ensure that your capability building efforts adapt to the changing needs of your attendees. Over 5 years at ELFT, we’ve moved beyond the innovators and early adopters, and with this comes the need to adapt the way in which we engage and support people to learn and apply quality improvement. We revise our capability building plan every year, to take stock of where we are, where the gaps are, and how we plan to meet these. Here’s some images to show how our capability building plan has evolved from 2015 through to 2019:

My third key learning about improvement capability is to approach this topic in a way that gives the actual projects the best possible chance of success. If we view capability building as a path to improving organisational performance, we realise that we also need to ensure that projects have a robust and close support structure, with skilled improvers available to guide and senior sponsors showing curiosity and attention to the work. This necessitates building skills at different levels within our workforce at the same time, so that those at the Board are learning the skills and applying them to their role in quality improvement, at the same time as sponsors, improvement coaches and teams of staff and service users. This helps with one of the key challenges with quality improvement that I hear so often – that people have developed the skills, but don’t have the time to apply them. If we’re working at multiple levels, we have a better chance of team leaders and senior leaders seeing the value of quality improvement, and helping ensure that their teams of staff and service users have protected time to work together in solving our most complex quality issues.

You can read all past QI Essentials posts here.

Most Read Stories

-

Why is Quality Control important?

18th July 2018

-

An Illustrated Guide to Quality Improvement

20th May 2019

-

2016 QI Conference Poster Presentations

22nd March 2016

-

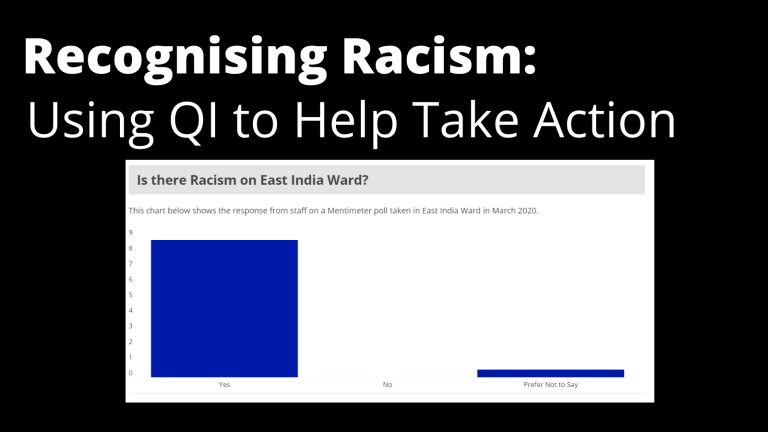

Recognising Racism: Using QI to Help Take Action

21st January 2021

-

Using data enabled us to understand our problem

31st March 2023

-

QI Essentials: What does a Chief Quality Officer do?

18th March 2019

Follow QI on social media

To keep up to date on the latest concerning QI at ELFT, follow us on our socials.