QI Essentials: Beyond Projects

25th November 2019

Improvement is now becoming a way of life and a way of being. How do we hold onto and strengthen our approach to QI projects?…Have a read of Amar’s latest QI Essentials Blog..

Since we began our quality improvement journey in 2013-14, QI projects have been the mechanism through which we have achieved breakthrough performance. Wrapped around the single question of “what matters most?”, QI projects have brought together a diverse group of stakeholders close to the issue to discover solutions to complex problems, achieving improvements that were previously inconceivable. Our QI approach across the organization has never focused solely on projects, as even our very first driver diagram from 2014 below shows.

We placed just as much emphasis on building will, building improvement capability and creating alignment and support for QI work. Yet the basic structure of a QI project has served us well over the last 5 years. It brings focus, it enables permission, it creates a space to think and imagine, it supports rapid cycle testing…

Over time, we have built belief in the utility of applying quality improvement to solve complex problems, through the systematic method, testing and learning, measuring over time, and deeply involving those closest to the issue. We have also supported 3000 people to learn improvement skills and tools, enabling us to speak a common language and be more effective in the way we understand and solve problems. It’s probably no surprise then that people are now starting to see improvement as a way of life, and a way of being – constantly searching for ways to improve, never being completely satisfied with the status quo, and applying their improvement knowledge to the everyday challenges that we face at work, whether or not these are part of a QI project.

Over the last few weeks, helped by our partners at the Institute for Healthcare Improvement, we have been talking about how we move beyond QI projects. It seems obvious that if improvement thinking and tools are only applied within QI projects, we will fail to harness the true opportunity of quality improvement. So, how do we hold onto and strengthen our approach to QI projects, whilst also enabling and supporting people to utilise their improvement knowledge and skills in everyday work?

Quality management

For me, there are two parts to this answer. Firstly, we need to utilise our quality management system as our approach to helping us manage and improve quality of all that we do. We can’t apply quality improvement continuously – anyone who has been part of a quality improvement effort will realise that this would be exhausting! Quality improvement should be a burst of effort to achieve a step-change in performance. Alongside QI, we need to recognise when we need good quality control, quality assurance or quality planning. As we become more adept at recognizing and deploying a particular aspect of our quality management system to an issue, we will be able to apply our ‘quality’ thinking to all that we do.

Depending on our role, we spend our time in different parts of the quality management system. Most of us spend the majority of our time doing the day job, with perhaps a few hours a week devoted to a quality improvement effort. We would benefit from a robust quality control system that allows us to understand quality and performance in a rounded sense, as close to real-time as possible, identify issues and solve them rapidly as a team. Our improvement mindset and tools are completely applicable to managing our service on a day-to-day basis as part of quality control.

Those of us in team leadership roles will spend some of our time in quality control, but more time focused on quality improvement and perhaps some time in quality planning. And those of us in senior leader roles spend much more time in quality planning – developing and executing strategy, with some time authorizing and sponsoring improvement efforts, and much less time in quality control. Whichever part of the quality management system we find ourselves in, our improvement mindset of being solution-focused and trying to influence the system we work within is an asset. The tools we have learnt through quality improvement may be of help to us, even when we find ourselves in quality assurance mode, or quality control or quality planning. Simple examples of this are the driver diagram, which has helped us visualise our strategy as a Trust (quality planning), or statistical process control charts, which help us understand how our system is performing (quality control).

When do we not need a QI project?

The second part of the answer lies in understanding when a QI project is the best approach, and when it isn’t. We have learnt, mostly through our failures, when to apply formal quality improvement projects to solve a problem – when the problem is a complex adaptive one, when it will likely require testing and learning to discover the solution, when we need a diverse team of stakeholders to understand the system from multiple perspectives, when the support of an improvement coach and sponsor will be helpful in guiding and supporting the work… But many of the challenges we face in our daily work don’t fit this description. Does that mean we can’t use quality improvement?

When I’m trying to improve the way my outpatient clinic functions to try to make sure I don’t keep running late, many of the factors are within my direct control. Do I need to set up a formal QI project, and get approval from a sponsor, in order to work on improving the flow of the clinic? Probably not. But I can apply my improvement learning to understand the problem through a fishbone diagram, create a driver diagram to better understand the factors related to a smooth-flowing clinic, develop ideas and test these out in my daily practice, keep track of key data to understand whether we are improving over time. I may not even need a formal team to work on this, or meet regularly, in order to improve the functioning of the clinic. But the discipline of improvement, with a systematic method and approach, will likely be helpful to me in tackling this problem.

There are lots of little things that we identify in our day-to-day work experience that could be improved. Not all of these are complex problems. We might feel that we understand the problem, and can even identify a solution that could fix it. Do these things need a project? Again, most probably not. We can just go ahead and try to solve the problem, without even always needing approval or permission. This is the ‘just-do-it’ approach. It might also be useful to apply the PDSA discipline of having a clear theory and prediction before we ‘just-do-it’, planning the test of change and having a way to understand whether it had the effect we were predicting. Of course, we may find that our solution doesn’t work, or needs broader engagement with the team. Then we may need to rethink whether this really is a simple ‘technical’ problem.

So there are potentially lots of ways in which we can apply our improvement mindset, but also our improvement tools, to solve problems outside of QI projects. It’s natural to conflate quality improvement with quality improvement projects, as that has been the typical way in which we have applied our quality improvement tools and knowledge to solve problems. But there is huge utility for quality improvement outside of projects. Tools such as flowcharting, or fishbone diagrams can help us understand the system better. The principles of PDSA can be applied for simple changes we want to make on an everyday basis, without having to sit within a QI project. We will continue to need QI projects for those big, complex quality and safety issues for which we need to bring together a diverse group of stakeholders, discovering solutions through testing and learning with close support. But lots of other opportunities for improvement don’t necessarily need a QI project. Our challenge is to retain the situational awareness to recognise these opportunities, hold onto our mindset that we can influence the system to make things better, determine whether the opportunity would benefit from a formal QI project structure or not, and then apply our improvement tools to make a difference.

Most Read Stories

-

Why is Quality Control important?

18th July 2018

-

An Illustrated Guide to Quality Improvement

20th May 2019

-

2016 QI Conference Poster Presentations

22nd March 2016

-

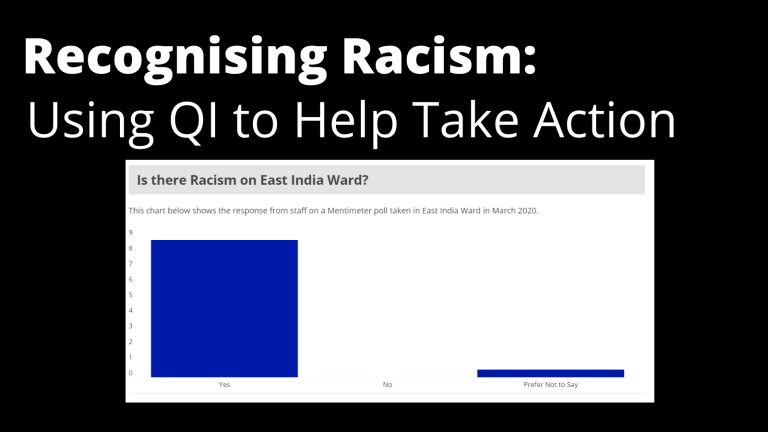

Recognising Racism: Using QI to Help Take Action

21st January 2021

-

Using data enabled us to understand our problem

31st March 2023

-

QI Essentials: What does a Chief Quality Officer do?

18th March 2019

Follow QI on social media

To keep up to date on the latest concerning QI at ELFT, follow us on our socials.