QI Essentials: More than a set of tools…

11th August 2020

There’s no doubt that quality improvement employs a large set of tools – driver diagrams, statistical process control charts, Pareto charts, force field diagrams, cause and effect diagrams, PDSA cycles, affinity diagrams, flow charts… The list could go on and on. Indeed, one of the comforts that quality improvement brings is the chance to build experience with a repertoire of tools that can help us as a team view systems and processes, gather information, organise information, understand variation and relationships between factors. Knowing that there is a tool to use in a given situation helps build belief that there is value in applying a systematic approach to solve a complex problem. As an organisation or system builds improvement capability, there is additional comfort from the increased fluency that builds across a community of improvers with these tools, which provide practical and helpful structure when working through complex problems, much as a structured risk assessment tool helps frame a clinical team discussion and decision-making. Most of these improvement tools are more powerful when applied by a team of staff and service users working together, and so utilising tools together as a team can help create and reinforce the cultural aspects of quality improvement such as a flattened hierarchy, equal voice, inclusivity, shared purpose.

A summary of core quality improvement tools from the Improvement Handbook (Associates in Process Improvement)

The extensive use of tools within quality improvement has led some to ask if quality improvement is simply a toolbox – a set of tools that one applies within a broader approach to change. Are we applying and embedding quality improvement if we are just utilising tools at appropriate times? There appears to be an increasing narrative that using process mapping to understand a system, creating a driver diagram to help visualize our theory of change, or using statistical process control charts to view variation demonstrates that we are applying quality improvement.

It’s fantastic that teams are seeing the value of using QI tools as part of their daily work, helping them view the system, organize information or understand variation. In my view though, this isn’t sufficient to truly build a culture of continuous quality improvement. At ELFT, we encourage the use of QI tools – something we describe as daily improvement. However, we need to also recognise that using tools in our daily work misses the opportunity of applying rigour and a burst of energy within formal quality improvement projects to achieve breakthrough levels of performance.

Quality improvement projects also employ tools, but in pursuit of solving a complex quality issue and achieving an aim that really matters to service users and the team. Without the use of structured projects applying the quality improvement method for 6-9 months on a complex issue, we run the risk of getting better at the daily operational challenges, without really tackling the complex, more strategic, longer-term challenges that require us to think differently and discover new ways. Of course, the quality improvement project requires us to create temporary project teams and dedicate resource to work on the issue, which creates a healthy tension with the demands of delivering the day job. Perhaps this might be one reason for people preferring to see quality improvement as a set of tools for teams to apply when they see the benefit, rather than an approach to applied problem solving for both daily challenges and the more strategic long-term challenges.

Continuous quality improvement also requires a change in leadership mindset – devolving problem-solving to the point where the problem is experienced, actively supporting broad involvement in experimentation and improvement activity, encouraging those we lead to take a systematic approach to problem-solving, creating an environment where people feel safe to speak up and contribute to improvement.

In the Toyota production system, the word ‘kata’ describes the set of behaviours and habits that enable the organisation to continually improve. The word kata comes from the choreographed movements practised in martial arts.

Within the management system developed at Toyota, there are two forms of kata – the improvement kata, and the coaching kata. The improvement kata involves four steps:

- Understand the direction or challenge (clarifying the long term goal or vision)

- Grasp the current condition (understand the current system and issues)

- Define a target condition (set an improvement aim)

- Experiment towards the target condition (test new ideas using a structured Plan-Do-Study-Act process)

Most improvement practitioners would recognise the improvement kata as the core steps for any improvement method, and fundamental to the design and delivery of QI projects.

The coaching kata redefines the role of leaders as guiding learning and application of the PDSA cycle to navigate uncertainty in order to achieve the target condition. This involves asking questions instead of providing solutions, and transmitting confidence. It is believed that one can only teach something and convey confidence if they themselves have tried it and mastered it. So leaders can only become good coaches if they themselves have been a learner, and have adopted the improvement kata to solve problems.

I think this is helpful in showing us that using QI tools as part of daily work can support embedding of improvement into the way our team works together and tackles challenges on a day-to-day basis. To truly adopt the improvement kata, we need to also apply quality improvement to identify our biggest challenges, and discover our way to new levels of performance through structured experimentation. All of this relies on leadership that has first-hand experience and expertise in quality improvement, and adopts the coaching kata in guiding and supporting teams through the complex challenges they are working through.

Find all of Amar’s blogs here >>

Most Read Stories

-

Why is Quality Control important?

18th July 2018

-

An Illustrated Guide to Quality Improvement

20th May 2019

-

2016 QI Conference Poster Presentations

22nd March 2016

-

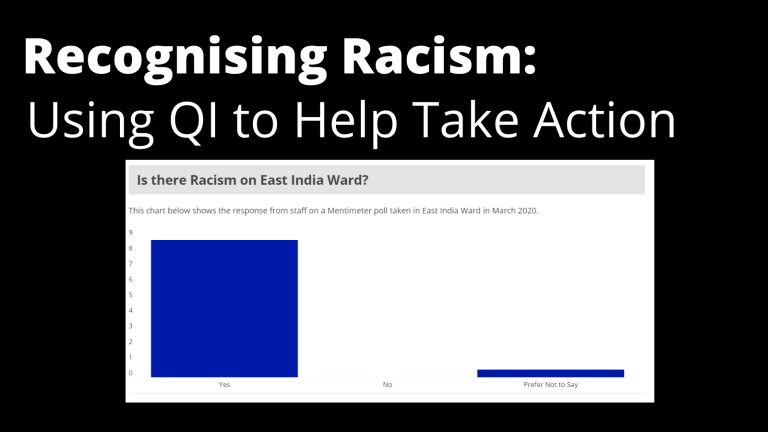

Recognising Racism: Using QI to Help Take Action

21st January 2021

-

Using data enabled us to understand our problem

31st March 2023

-

QI Essentials: What does a Chief Quality Officer do?

18th March 2019

Follow QI on social media

To keep up to date on the latest concerning QI at ELFT, follow us on our socials.