Flow Charts

Creating Flow Diagrams and Process Mapping is used to develop a ‘map’ of a process within a system. It will help you to map the whole patient journey or diagnostic pathway with a range of people who represent the different roles involved. Process mapping can be used to help a team understand where the problems are and identify areas for improvement.

How to use it

The aim of process mapping is to make things clear and to provide insight. The best map is often the simplest map.

There are different approaches to process mapping. Which one you select will depend upon what you need to know, what level you are working at (whole pathway or a small part of it), resources available and timescales.

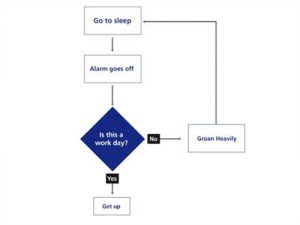

Start with a high level process map of say 5 to 10 steps which you set a time limit to achieve e.g. 20 minutes. This helps to establish the scope of the process and identify significant issues. Here is a simple example of a high level process map.

Key to process mapping

| Box | Shows the activities of the process. |

| Diamond | Represents the stage in the process where a question is asked or a decision is required. |

| Oval | Shows the start of a process and the inputs required. Also used to mark the end of the process with the results or outputs. The symbol is the same for the start and end of a process to emphasis interdependency. |

| Arrows | Show the direction or flow of the process. |

There is software that can help you to develop process maps but in a group setting you can use rolls of paper (lining paper from a DIY store); marker pens, post-it notes in different colours to represent the four different symbols, flip chart to ‘park’ issues and display ground rules for your session.

Once you have your high level process map you will start to be able to understand how the process works and where there are problems, drilling down into these with more detailed process maps. Further work maybe required to analyse the problem areas identified e.g. seek stakeholder feedback or further data collection. The information and level of detail required will depend on the scope of your project. The Aims Tool and the Driver Diagram may be useful tools to help you clarify this.

Scope

- What do you need to know?

- How simple can you go?

- Are you working at a high-level or focusing in more detail?

Knowing whose views you will need to inform the improvement is important. You should consider:

- Whose views do you need?

- How will you engage those individuals?

- How will you capture their views?

Ideally you will know what your problem areas such as the point in your process where a constraint causes flow to be slowed. This may already have been identified right at the start of the improvement journey when developing your project charter.

The Science of Improvement on a Whiteboard with Robert Lloyd, Vice President, Institute for Healthcare Improvement

Follow QI on social media

To keep up to date on the latest concerning QI at ELFT, follow us on our socials.