Developing, rapid cycle testing and scaling an idea within a day for PPE ordering

24th April 2020

By Marco Aurelio, Improvement Advisor

2021 Update: The team went on to update their flowchart as they iterated on the design of their process for ordering and delivering Personal Protective Equipment (PPE). This soon developed into designing a warehouse process that now employs staff with supply chain skills and specialist software to manage the process of ordering and delivering PPE across the organisation.

True or false? Using quality improvement methodology is slow, cumbersome and not relevant when dealing with a crisis?

Colleagues from the Procurement team, Infection Control, Community Health Newham, Communications and the Quality Improvement department at East London NHS Foundation Trust (ELFT) worked collaboratively to use improvement tools and methods to test, iterate and standardise the existing manual process for ordering PPE (Personal Protective Equipment) into a faster digital process within a single day. Running a first test with a clinical team within 3 hours of starting this piece of work, we tested at scale four hours later and then implemented the process across the organisation the following day.

The Challenge

The process for ordering PPE relied partly on teams sending in their requests for PPE by email and those orders being fulfilled by a team of staff and volunteers that were put together to keep teams supplied. This sometimes involved back and forth conversations to get missing information about quantities needed, type of PPE, delivery locations, stock reconciliation and so forth.

What we did?

The team began by working together using a process map/flow chart to understand the current process for staff ordering PPE and some of the challenges that presented. From this, the team decided that a standardised online form would be helpful to both simplify user ordering and help with tracking orders and stock.

This provided a great opportunity to apply some of the principles of improvement to test and iterate quickly using a PDSA (Plan, Do, Study, Act) cycle. PDSA cycles make it possible to learn quickly and make changes based on that learning. Below is an extract of a PDSA form to describe how this group developed a new standardised process for ordering PPE.

Plan: Plan the test, including the plan for collecting data

- Question: Can an online form be easier to use for ordering PPE than an email?

- Prediction: The form would make it easier to submit requests but that there may need to be some clarifications over the amount of PPE to order

- Who: Three members of the QI team and two members of a Community Health team.

- What: Testing the online Microsoft Form for PPE using video conferencing and screen sharing on Microsoft Teams.

- When: 22nd April for 30 mins

- Data: Qualitative user feedback on what works and what needs changing on how to submit an order using the form

Do: Run the test on a small scale

What happened?

- Two colleagues from Community Health Newham, Improvement Advisors and a Data Analyst joined the call

- They worked through the form in real time on the call

- We collected feedback about what worked and what didn’t

- They checked the output in the back-office Excel database for the order placed

Study: Analyse the results and compare to the predictions

- The users highlighted the form was easy to use and captured the information they needed to perform a PPE request

- They were able to complete the form in about 6 minutes

- There needed to be some guidance signing into Microsoft office 365 account to validate the user and allow them to complete the form

- There needed to be some clarity over the quantity of certain items (e.g. number of gloves in a box)

Act: Can we adapt, abandon, adopt

- Adapt the form by applying the changes identified in the test

- Test the form under different conditions with more users

Below you can see the test in action and an extract of the order form:

Key learning

- A quality improvement tool like PDSA can easily be deployed outside of a formal quality improvement project to learn quickly around a solution

- Even in pressured environments like responding to challenges brought on by COVID-19, improvement tools can facilitate quick learning and iteration on what works and what doesn’t and bring some clarity.

- Once an idea has surfaced, look to run a small test as soon as possible with as few people as possible

- Test as often as is possible

- Include users and owners of the process/system in developing and testing any ideas for change.

If you are keen to learn more about using PDSA to test on a small scale you can use the resources here>>.

Have you used any quality improvement tools or approaches as part of new way of working in response to COVID? Let us know by sharing your story here>>

Most Read Stories

-

Why is Quality Control important?

18th July 2018

-

An Illustrated Guide to Quality Improvement

20th May 2019

-

2016 QI Conference Poster Presentations

22nd March 2016

-

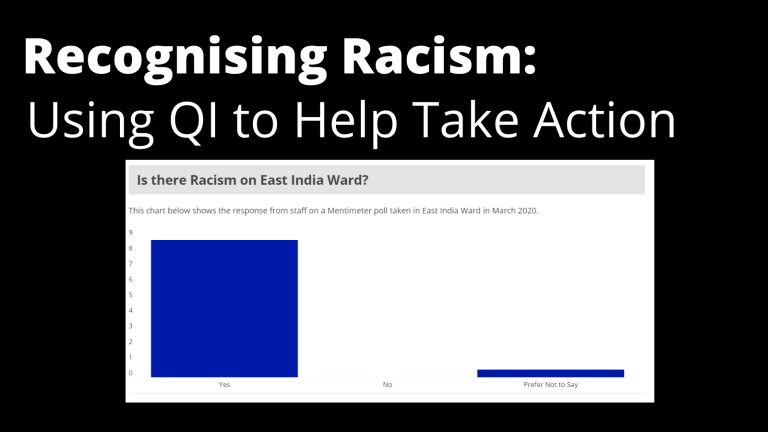

Recognising Racism: Using QI to Help Take Action

21st January 2021

-

Using data enabled us to understand our problem

31st March 2023

-

QI Essentials: What does a Chief Quality Officer do?

18th March 2019

Follow QI on social media

To keep up to date on the latest concerning QI at ELFT, follow us on our socials.